DRA – Drag Reducing Agents

SOGS present itself as a leading provider of Drag Reducing Additives (DRA) to improve pipeline flow in onshore and offshore pipeline applications. SOGS DRA reduces drag in petroleum pipelines in order to increase throughput capacity and energy efficiency.

SOGS present itself as a leading provider of Drag Reducing Additives (DRA)

Sahara Oil & Gas Services LLC presents itself as a leading provider of Drag Reducing Additives (DRA) to improve pipeline flow in onshore and offshore pipeline applications. SOGS DRA reduces drag in petroleum pipelines in order to increase throughput capacity and energy efficiency.

Features / Benefits

- DRA Benefits flow to the bottom line.

- DRA have reduced energy loss to friction by up to 80%.

- Have increased flow rates by up to 100 %.

- The results are nearly instantaneous upon injection.

- Performance depends largely on the properties of the fluid being transported and the condition of the pipe-line.

DRA can bring substantial improvement to your bottom line profit by maximizing the flow potential and throughput capacity of your pipelines, saving energy, and giving your operations greater flexibility. This can be achieved for minimal cost per incremental barrel, while requiring no capital investment.

Product Information

Drag Reducing Additives are specially formulated for use with a broad range of crudes and fuels in different pipe-line conditions and environments. All our formulations do not alter the fluid shipments.

Independent laboratory testing has confirmed that SOGS DRA do not impact fuel specifications, and engine testing has demonstrated that a polymer concentration up to 15 ppm in gasoline does not affect fuel quality or engine performance.

DRA: Drag Reducing Additives

DRA are Non-Hazardous and Environmentally friendly product.

To ensure a flawless application of our products, SOGS also offers;

- Injection equipment for each application.

- Experienced Field Service personnel to install and perform maintenance to injection units.

- Pipeline hydraulic analysis to optimize DRA dosage and maximize savings.

How DRA Works

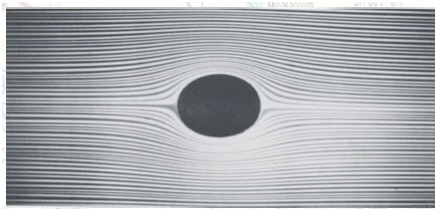

Improve flow in pipelines by reducing turbulence. They can dramatically increase flow or sustain a given flow rate using less energy.

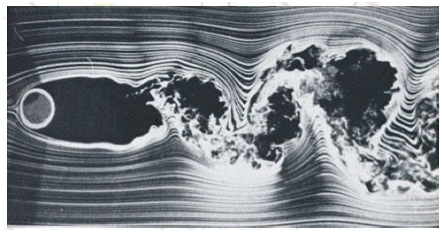

In most petroleum pipelines, flow is turbulent. Non-linear currents and frictional resistance, consume much of the energy applied to move the fluids. DRAs are long-chain polymers that reduce friction near the pipeline wall and within the turbulent core, dampening rotational flow, decreasing energy loss, & thereby allowing more efficient use of the pumping energy.

Fig 1. – Turbulence before DRA injected.

Fig 2. – Linear flow patterns after DRA injected.

DRA Application Types

Flow Increase

The most common use of DRA is to increase pipeline flow rates in a system that is at capacity. In order to deliver more hydrocarbon fluids in the system, DRA is injected at each segment to increase the overall pipeline capacity.

DRA usage is very cost effective versus capital intensive mechanical expansion. In addition to no capital requirements to achieve the extra flow, the desired incremental increase is nearly instantaneous upon injection!

This type of application is utilized in many oil producing regions. Many of our customers are using DRA to increase field production by more than 50% with ppm levels of injected DRA. The cost is minimal per incremental barrel produced.

Pipeline Flow Increase

Increase Flow Rate of 1 or many Pipeline Segments

Increase Tanker Loading Rate

Increase FSO Loading Rate

Pressure Reduction

Pipeline operations depend on pumping pressure as their lifeline to deliver flow capacity. Due to aging systems, corrosion, abrasions or a pipe-line bottleneck, pressure constrains become a pipelines Achilles heel.

Multiple worldwide customers use DRA to manage pressure constraints and or en-able typical capacity at lower pressures.

Pipeline Pressure Reduction

Reduce Operating Pressure to handle Corrosion problems

Reduce Operation Pressure due to Maintenance

De-bottleneck Connected Platform Infrastructure

Energy Savings

Drag reducing additives are commonly used to maintain a pipeline’s flow rate while bypassing a pumping station that is down temporarily for service or repair. A large U.S. pipeline operator, however, is using DRA as a permanent pump replacement.

This innovative approach has allowed the opera-tor to bypass half of the pumping stations on the system and significantly lower overall energy use. This energy hedge delivers a significant seven-figure dollar savings each year, reduces maintenance and repairs costs and provides a green alternative to energy usage.