DRS Injection System

Injection Skid Model: 1N6150-2H-SAV

The mobile dosage unit is designed and built to inject Drag Reducing Chemicals into flowing hydrocarbon pipelines. It is comprised of a pneumatic-driven diaphragm transfer pump, suction manifold, pressure relief valves, pressure gauges and vent valves, mass flow meter and motor control panel, assembled on an industrially painted, oil-field, steel base.

Injection Skid Model: 1N6150-2H-SAV

The mobile dosage unit is designed and built to inject Drag Reducing Chemicals into flowing hydrocarbon pipelines. It is comprised of a pneumatic-driven diaphragm transfer pump, suction manifold, pressure relief valves, pressure gauges and vent valves, mass flow meter and motor control panel, assembled on an industrially painted, oil-field, steel base.

The unit is rated for use in a hazardous atmosphere, and complies with NEC Class I, Division II. The pump injection is a hydraulically actuated diaphragm pump. Injection rate is controlled by adjusting the pump stroking speed by changing the motor speed with a Variable Frequency Drive (VFD).

The VFD contains a PID loop controller which maintains a flow rate set point that is locally set. A local display on the flow meter shows the current injection rate and the total volume pumped.

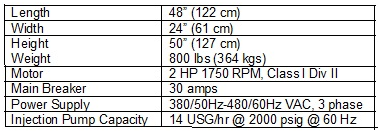

Specifications:

Frame Portable Test Skid

IBC Tank

IBC Tank

Specifications: IBC Tank

- Approved for filling products of a maximum density of 1.9

- Perfectly suited for high bay warehousing (specially reinforced bottom plate prevents deflection).

- Can be stacked up to 4-high.

- Reinforced, warp resistant tubular steel grid jacket.

- Additional corner guards to protect the inner container.

- Available in a variety of equipment packages.

- extrusion blow-moulded HDPE

- SMP protective barrier (optional)

- additional UV and light protection of the filling product(optional)

Outer container

Welded tubular steel grid, galvanized

Bottom plate

Made of steel plate to provide stability and to facilitate minimum residual contents from the inner container

Certification

UN 31 HA1/Y (optional)

Maximum density 1.9